lyophilization

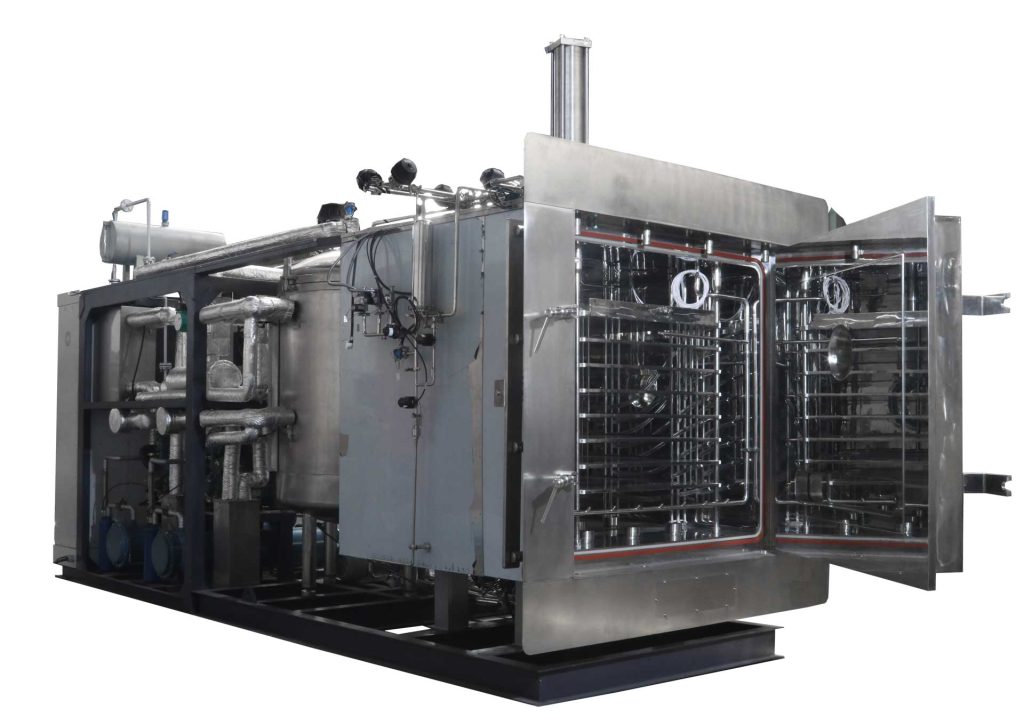

Freeze-drying, or lyophilization, performed by the pharmaceutical freeze dryer, is a preservation and drying process in which the water present in the sample is sublimated (direct conversion from a solid to a gas) without going through the liquid state. This method is used to preserve drugs, food substances, biological materials, and other moisture-sensitive materials.

This method, compared to other heat-based drying methods, removes the moisture from drugs without altering their properties. Therefore, it is considered the best option for producing high-quality products, especially in the pharmaceutical industry. Additionally, the freeze-drying process using the pharmaceutical freeze dryer can effectively prevent chemical changes and contaminants present in the sample, protecting sensitive materials from degradation and contamination.

History of Parseh Industrial Group:

The company was formed with the aim of undertaking engineering projects in fields that involve advanced technologies right from the beginning. In the early years, the company engaged in various projects in areas such as energy, transportation, oil and gas, and more, from 2009 to 2012, accomplishing successful projects in these fields. In 2013, the company’s board of directors decided to design exclusive products in a specific domain for the first time in the country, leading to the establishment of a production facility. Towards the end of 2013, the concept of designing and manufacturing freeze dryer machines was introduced, which gained approval, and the entire engineering and financial focus of the company shifted to this matter.

From that year onwards, the company has been dedicated to the design and production of various types of freeze dryer machines and has succeeded in designing and manufacturing freeze dryer machines with various applications in the pharmaceutical and food industries, with different capacities.

Since 2021, the decision has been made to meet the requirements and international standards and to prepare the groundwork for entering foreign markets to sell freeze dryer machines. To achieve this goal, projects were initiated, including:

- Adaptation of the machines’ software to the requirements of 21 CFR Part 11

- Design and construction of Auto Loading & Unloading systems

- Enhancement of the quality level of machine parts production through the definition of automatic mechanical welding and polishing and electropolishing projects

Alongside these actions, the company has obtained CE certification and is currently exploring the establishment of an assembly site in one of the target countries to facilitate international relations.

With a systematic program continuously being monitored, the company aims to become one of the world’s leading brands in the design and manufacture of pharmaceutical and food production equipment by the year 2030.